Why Fabric Barns Are The Future Of Sustainable Farming

If you’re running a farm in Canada right now, you’re juggling a lot: unpredictable weather, tight margins, labour shortages, and pressure to operate more sustainably. The good news? One upgrade can improve cost, comfort, and climate resilience simultaneously: fabric barns.

Below, I’ll walk you through why these buildings make sense for modern, sustainable agriculture, how they perform in Canadian conditions, and what to consider when choosing and installing one. I’ll keep it practical and friendly, like we’re chatting over coffee at the kitchen table.

Why The Future Of Sustainable Farming Points To Fabric Barns

The future of agriculture is about doing more with less: using less energy, generating less waste, and experiencing less downtime. Fabric barns (also called tensioned-fabric or membrane buildings) check those boxes:

- Lower embodied materials than traditional stick-built or all-steel barns.

- Fast installation so you’re up and running sooner (revenue starts earlier).

- Efficient interiors with natural light and smooth airflow, reducing electricity use and moisture issues.

- Modular and adaptable as your operation grows or changes.

That’s why more sustainable farms are weighing fabric structures alongside conventional barns when they think about the future of agriculture and long-term capital planning.

What A Fabric Barn Is (And Why It Works)

At a high level, a fabric barn combines a galvanized steel frame with a high-strength, UV-stabilized fabric membrane that’s tensioned tight. This creates a strong, weathertight shell with a bright, open-span interior. With no central columns, you get flexible layouts for livestock, hay, or equipment and easy maneuvering for loaders and trucks.

Key Performance Advantages

1. Daylighting Saves Energy

The white or translucent membrane floods the interior with daylight, so you can work most of the day without flipping a switch. This goes straight to your Hydro bill and supports sustainable farming methods and techniques focused on energy reduction.

2. Natural Ventilation and Better Air Quality

The curved profiles and ridge/side vent options move air naturally. Good airflow helps control humidity, lowers ammonia buildup in livestock settings, and reduces condensation on equipment and stored feed. Put simply, fabric buildings improve airflow, which supports animal comfort and reduces maintenance headaches.

3. Weather Resilience in Canadian Conditions

From heavy snow in the Prairies to salt air on the coasts, the right spec’d fabric barn qualifies as a weather-resistant building. Proper snow and wind ratings, engineered trusses, and hot-dip galvanized steel help the structure resist corrosion and loads season after season. This is core to extending your barn’s lifespan.

4. Healthier Environment for Animals and People

Bright interiors and gentle air movement reduce stress and improve the working environment. Many producers report calmer animals and less odour buildup, small daily wins that compound over time.

5. Faster, Lighter Foundations

Depending on soil and building size, many fabric barns can sit on screw piles, concrete blocks, or grade beams rather than a full slab. That keeps costs down and accelerates construction, one reason prefabricated building solutions are the future for busy farms.

Everyday Farm Uses Where Fabric Shines

Fabric barns are versatile. Here are common use cases that make sense across Canada:

- Livestock Housing: Beef, dairy, poultry, and equine. Open-span layouts allow pen changes, robotic milkers, or bedding tweaks without major structural work.

- Feed and Hay Storage: Keep bales dry and reduce spoilage with steady ventilation.

- Equipment and Vehicle Storage: Protects combines, sprayers, and service trucks from UV and condensation.

- Compost, Sand, and Salt Storage: For mixed operations or municipal contracts.

- Wash Bays and Workshops: Wide doors and open interiors are easy to organize and clean.

- Personal Storage: Boats, RVs, or a farm “supply shed” that doubles during harvest crunch time.

For West Coast producers, fabric buildings for BC farmers are especially helpful in wet climates where constant rain challenges ventilation and mold control.

Choosing a Shape: Arch Vs. Peak (And Why It Matters)

You’ll see two common roof profiles: arch-shaped buildings and peak-shaped buildings. Both can be engineered for snow and wind, but the shape changes how they behave and how you’ll use the space.

- Arch-shaped buildings

- Great for shedding snow naturally.

- Excellent airflow and interior brightness.

- Often a touch more economical per square foot.

Clean, modern look that suits hay/equipment storage or free-stall barns.

- Peak-shaped buildings

- Traditional profile with more vertical wall height, which helps with tall racking, mezzanines, or stacked storage.

- Easier to integrate large ridge vents and overhead doors at the gables.

- Aesthetic match for sites with other peaked structures.

Can’t decide? Think through clearances for equipment, how you’ll place doors, and your local snow patterns. Many farms mix: arch for hay and cattle, peak for shop/maintenance.

Plan For Efficiency From Day One

If you’re making the jump, use the build to maximize farm efficiency:

- Traffic flow: Position doors for drive-through paths and fewer tight turns.

- Ventilation: Add roll-up sides or ridge vents to leverage prevailing winds.

- Lighting: Even with daylight, install efficient LEDs for early mornings and winter afternoons.

- Flooring and drainage: Good grades and drains mean quicker cleanups and drier bedding.

- Future utilities: Stub in water, conduit, and data so upgrades are painless later.

This is also where building solutions for agriculture providers earn their keep; the best partners will model layouts for animal flow, bedding changes, and service access.

Installation: What To Expect (And How To Do It Right)

Curious about how to install fabric buildings? Here’s the short version:

- Engineering & Permits: Confirm snow/wind loads for your municipality and obtain permits.

- Site prep and foundation: Grade, compact, and set piles or grade beams as specified. Proper base work pays off in long-term stability.

- Frame assembly: Trusses and columns are set, braced, and anchored.

- Membrane tensioning: The fabric is draped, aligned, and tensioned to spec (this step is crucial for performance and longevity).

- Doors, vents, and accessories: Add end walls, doors, fans, curtains, and electrical.

- Final inspection & tune-up: Verify tension, fasteners, and safety clearances.

Pro tip: Budget a quick seasonal tune-up in year one as the fabric settles. It takes a few hours and keeps everything drum-tight. (More in seasonal tips for maintaining farm structures below.)

Maintenance That Actually Extends Life

Fabric barns don’t ask for much, but a little routine attention protects your investment and keeps them in top form:

- Quarterly Visual Checks: Look for abrasions at contact points and re-tension if needed.

- Keep it Clean: Hose dust/salt off the membrane; clear gutters and base.

- Manage Snow Loads: Most snow slides off curved profiles, but always follow the manufacturer’s snow-management guidance.

- Hardware Health: Check door tracks, hinges, and anchor bolts annually.

- Ventilation Checks: Make sure curtains and vents move freely.

Simple habits like these truly help with extending your barn’s lifespan.

Cost and ROI: The Practical Math

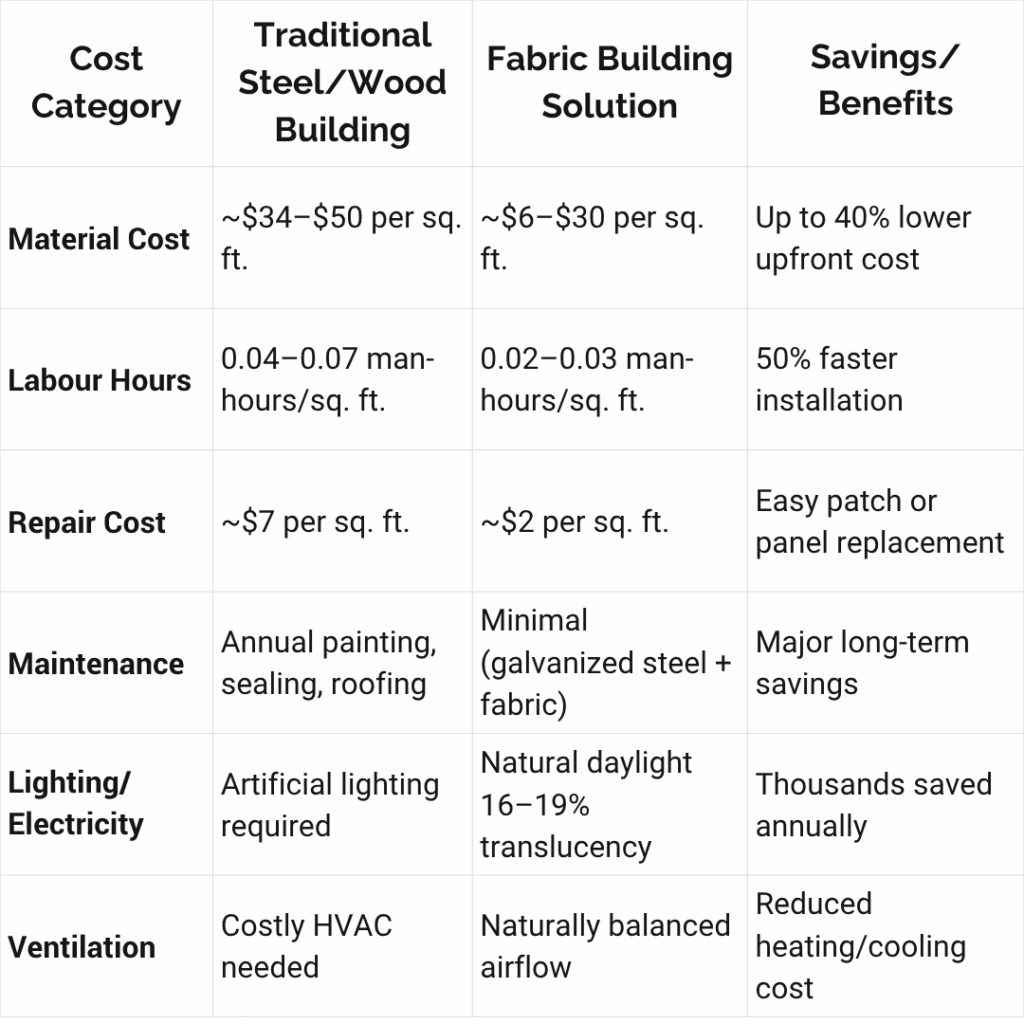

You care about payback, totally fair. Here’s where fabric often wins:

- Lower upfront cost per covered square foot versus traditional construction.

- Faster deployment, which reduces downtime and protects assets sooner.

- Reduced operating costs thanks to daylighting and airflow.

- Adaptability, if you change direction (more cattle, new crops, different storage), the building adapts rather than getting scrapped.

Add the resilience benefits, such as fewer moisture problems, corrosion control, and better working conditions, and fabric barns support the future of sustainable farming both financially and environmentally.

Beyond the Farm Gate: Community And Commercial Uses

One sign these structures are here to stay: municipalities and businesses use them widely for commercial buildings, industrial buildings, and municipal solutions (think road-salt sheds, transit depots, public works storage, and seasonal recreation). This broader adoption strengthens local supplier networks and parts availability, handy when you need a door panel tomorrow.

Seasonal Tips For Maintaining Farm Structures (Quick Checklist)

Canadian seasons are no joke. A simple rotation helps:

Spring

- Inspect anchors and posts after freeze-thaw.

- Wash membrane; check ridge/side vents.

- Service doors and latches.

Summer

- Confirm ventilation is keeping temps down.

- Trim vegetation back from walls.

- Touch up any galvanized coatings per manufacturer guidance.

Fall

- Clear drains, gutters, and door tracks.

- Check fabric tension ahead of winter winds.

- Test backup lighting and generators.

Winter

- Follow snow-load guidance; keep entrances and eaves clear.

- Watch for ice rub points near gates or equipment.

- Schedule your spring tune-up.

These small steps, year after year, reinforce weather-resistant buildings performance and longevity.

Thinking Ahead: Fabric Barns And The Future Of Agriculture

Let’s zoom out. The future of fabric buildings aligns with the future of sustainable farming: smarter materials, better airflow, energy trim, and flexible interiors that evolve with your operation. In short, fabric isn’t a compromise; it’s a strategic upgrade that supports animal welfare, reduces energy use, and gives you room to adapt.

And if you’re experimenting with regenerative practices, precision feeding, or low-carbon strategies, a fabric barn gives you the adaptable shell to trial new layouts and sustainable farming methods and techniques without rebuilding from scratch.

Ready To Explore? Here’s A Simple Path

- Define the job: Livestock, hay, equipment, or mixed use.

- Pick the profile: Shortlist arch-shaped buildings or peak-shaped buildings based on clearance, snow, and airflow.

- Map efficiency: Door placement, lanes, and pen layouts to maximize farm efficiency.

- Engineer for your site: Snow/wind loads and foundation choice.

- Plan the install: Work with a reputable partner and schedule a tension check post-build.

- Maintain lightly, consistently: Follow the seasonal checklist above.

If you’re aiming for a durable, adaptable barn that fits the realities of Canadian farming and supports a lower-carbon operation, fabric deserves a serious look. It’s a practical step toward the future of sustainable farming, one that makes your day-to-day easier and your long-term plan stronger.

Maximizing Farm Efficiency with Custom-Designed Fabric Structures

Ready to seriously optimize your farm’s productivity and squeeze every last drop of potential from your land? Then you’ve landed in the right spot. Let’s dive into a potentially transformative solution: custom-designed fabric building for farm operations.

I know, “fabric buildings” might sound a bit out there at first. But hold tight; these are practically engineered assets, cleverly designed to seriously amp up your farm efficiency and offer some solid protection for your livelihood.

Stick around and discover how these building solutions for agriculture could revolutionize your farm, optimize crop efficiency like never before, keep your livestock and equipment safe as houses, and generally help your operation run smoother and more profitably.

Custom-Designed Fabric Buildings: A Perfect Tailor-Made Fit

You know how vital it is to squeeze every ounce of productive power out of every square foot of your land, right? That’s where custom-designed fabric buildings really shine. Unlike your usual, run-of-the-mill structures, these buildings are built exactly to your needs. Big open area for livestock? Covered crop storage? Sheltered spot to fix equipment? Fabric buildings are molded to your farm’s unique layout.

Think of it like bespoke clothing, but for your farm. You pick the size, the form (from arch-shaped buildings to pointy peak-shaped buildings), and the materials that are just right for your climate and how you work. Need more space for that new combine? Killer airflow for your prize tomatoes? All are absolutely achievable.

Maximizing Farm Efficiency

You’ve probably heard that prefabricated building solutions are the future due to quick build times, cost-effectiveness, and surprising toughness. But custom-designed fabric buildings for farm solutions? They crank those benefits to eleven! These are a versatile, budget-friendly game-changer to seriously maximize your farm efficiency where it counts:

- Reduced Maintenance: Wave goodbye to endless repairs! Fabric buildings need minimal upkeep. The weather-resistant buildings mean fewer leaks, less painting, and way less hassle. You save time and money.

- Energy Efficiency: Traditional barns can trap heat and humidity like nobody’s business. Fabric buildings flood the space with natural light and boast superior airflow, keeping temps steady year-round. Translation: lower energy bills and a much healthier environment for your animals and crops. In short, fabric buildings improve airflow, which translates to fewer sniffles in your herd and zero mold in your prize-winning produce.

- Rapid Deployment: Fabric buildings can go up way faster than the old way. A traditional barn can drag on for months, while you can be fully operational with a fabric building in weeks. Less downtime equals more uptime.

Fabric Structures and Crop Efficiency: A Winning Team

When it comes to crop efficiency, it all boils down to crafting the perfect growing and storage setup. And a custom-designed fabric building for a farm? They rock this. The fabric lets in just the right amount of sun, plus great ventilation, and plus protection from bad weather.

- Temperature Control: Add-on temperature controls to your customized building to help your crops relax through summer and stay cozy in winter. The result is less stress from those temperature swings, boosted yields, and happier plants.

- Airflow & Ventilation: If you want healthy crops, you need killer airflow. Fabric buildings nail this. Natural ventilation drops humidity and kills off mold and mildew, making these buildings especially essential for high-moisture fruits and veggies.

- Weather Protection: Weather-resistant buildings mean you’re protected in just about any condition. Whether it’s a greenhouse or plain old crop storage, you can rest easier knowing your stuff is as snug as a bug.

Custom Fabric Buildings for Livestock: Happy Critters, Happy Farm

And while crops are critical, so is the health of your animals. Custom-designed fabric buildings for farm setups make life sweeter for everyone. Comfortable, secure, and simple to keep clean, these buildings lead to happier cows and horses.

- Better Airflow: Proper ventilation is an outright must for animal welfare. Fabric buildings naturally promote good airflow, mitigating the threat of respiratory problems often seen in poorly ventilated barns.

- Temperature Control: From sweltering heat through bone-chilling cold, fabric buildings can keep temperatures just right, minimizing animal stress and maximizing weight gain (if that’s your plan.)

- Low-Stress Environment: Let’s face it, metal barns can be rackety. Fabric structures are quieter and more peaceful because diffused light keeps animals serene and encourages production.

Built to Last: Extending Your Barn’s Lifespan

One of the best assets of custom-designed fabric buildings for farm use is simple durability. Putting your dollars in a quality fabric structure is an outright investment in a long life. building. These setups can’t be felled by rust, rot, or decay, common problems with traditional barns. Their inherent design gives them structural advantages in rough weather.

With a little bit of upkeep, your fabric building is sure to support decades of good service, extending your barn’s lifespan and guarding your farm’s core structure. Fewer repairs mean more money and more reliable operation for years to come. With the right care, their sustainability makes them the future of sustainable farming.

Seasonal Tips for Keeping Your Custom Fabric Building Tip-Top

Fabric buildings are inherently low-hassle, but these seasonal tips for maintaining a farm ensure smooth sailing:

- Winter: Keep an eye on snow buildup, especially after a big storm.

- Spring: Check the fabric for wear and make sure connections are secure.

- Summer: Let it breathe! Maximize ventilation to keep temps down.

- Fall: Scout your area for early signs of winter damage.

Here Comes Tomorrow: The Future of Fabric Buildings

Fabric structures are poised to take over farms everywhere! Driven by growing cries for sustainability, affordability, and raw durability, fabric buildings are becoming a clear choice.

Their versatility suits them for every need, from secure crop storage to durable livestock shelters. Farmers in BC and elsewhere are finding these buildings invaluable, whether related to agricultural purposes, traditional commercial buildings, or even personal storage. Be sure to explore how to install fabric buildings.

Spanmaster provides custom-designed fabric buildings for farm applications. Reach out and get your complimentary consultation today, and learn how the future of fabric buildings can build a brighter financial future for your farm. Contact Spanmaster today!

How Fabric Buildings Improve Airflow and Animal Health on Farms

Hey there, farmer! You know a happy farm starts with healthy animals. And what makes animals healthy? Great airflow. Fabric buildings might just be the surprisingly simple answer you’ve been overlooking. They’re not always the first thing that comes to mind when you’re thinking about farm buildings, but hear me out: fabric buildings improve airflow and improve animal health, and that could seriously boost your farm’s success.

Fabric Buildings: Your Secret Weapon for Better Airflow

Seriously, what’s the first thing that worries you about your animals? It’s got to be good air! That’s where fabric buildings for farms really shine. Unlike those old metal or wood barns, these building solutions for agriculture breathe. The fabric helps air move naturally.

This natural airflow helps manage temperature and humidity. That’s a lifesaver during the summer, when the heat can really stress your animals. Consistent temperatures and good airflow mean less stress for your animals and a happier, more productive farm for you.

Plus, with either the tall peak-shaped building style or the curved arch-shaped building design, air flows freely. Warm air rises, and stale air doesn’t stand a chance, which matters because stagnant air breeds bacteria.

Happy Animals: A Farm Transformation

You want the best for your animals. Fabric buildings offer an amazing indoor space. By making sure the air is just right and keeping the temperature steady, they cut down on respiratory problems, a common and costly issue in stuffy barns. This does more than keep your animals comfy; it helps you avoid expensive vet bills and keep your farm profitable.

Happy animals are less stressed, whether it’s a sweltering summer or a frosty winter. And less stress means fewer diseases, healthier animals, faster growth, and more production overall. It’s a win all around!

The soft, natural light that filters through the fabric is an extra benefit. Forget dark, cramped barns. Fabric buildings fill the space with gentle light, and that actually makes your animals feel better mentally. So, fabric buildings improve animal health.

Getting More Out of Your Farm: A Smart Move

Think long term. Fabric buildings can save you money and make your farm run more smoothly. They don’t cost a fortune to build, and they don’t need a ton of maintenance. Less patching and fixing, and more focus on actually farming. These weather-resistant buildings are tough. They stand up to whatever Mother Nature throws their way, so you won’t be constantly patching them up.

Did I mention they go up fast? We’re talking weeks, not months, to get a new building up and running, which means less downtime and more time actually working with your animals. Check out how to install fabric buildings.

Prefabricated building solutions are the future. They’re flexible, affordable, and quick to build, and you don’t have to stress about finding qualified builders to get the job done right.

Keeping Barns Around Longer

Smart farming means making your buildings last. Thinking about extending your barn’s lifespan? That’s key to protecting your investment and setting up a modern, efficient farm. Fabric buildings can really help with that, and they don’t need a ton of upkeep. The fabric they’re made from doesn’t rot or decay, unlike wood. And unlike metal, it won’t rust.

If you invest well in a good fabric building, you’ll save money on maintenance in the long run. Can’t beat that!

Quick Tips to Keep Your Fabric Building in Tip-Top Shape

Here are some easy seasonal tips for maintaining farm health and keeping your fabric building working its best all year long.

- Winter: Don’t let snow pile up too much on the roof. Clear it off!

- Spring: When winter’s over, look for any wear and tear. Clean out any junk that’s collected.

- Summer: Open doors and vents to keep the air moving and prevent things from getting too hot inside.

- Fall: Give the fabric a good once-over. Look for anything that might need fixing, and get ready for winter.

The Future is Green

With everyone focusing on sustainable farming, fabric buildings are becoming popular fast. They’re eco-friendly, they don’t break the bank, and they’re a smart choice for sustainable farming. Modern fabric buildings are versatile, and they’re only going to get better as building technology improves. Whether it’s fabric buildings for BC farmers or farmers anywhere, these buildings are helping people make their farms more efficient and create better spaces for their animals and crops.

Are you ready to boost your farm’s performance and invest in its future? Choosing tough, versatile fabric buildings could be just the answer.

Want to find out more about how expertly crafted fabric buildings could change the way you farm? From innovative commercial buildings to strong industrial buildings, practical municipal solutions, or even simple personal storage, reach out to us and let’s talk about what you need!

Weather-Resistant Agricultural Buildings That Protect Your Investments

For a farmer, smart investing means more than just healthy crops and robust livestock. You need agricultural buildings, including barns, storage, and whatever keeps your operation humming.

Out here in Canada, be it blizzards or scorchers, good weather-resistant buildings are worth their weight in gold. Think secure livestock, safely stored grain, and equipment ready to roll. That’s how you keep things running smoothly and protect your hard-earned dollars.

So, what’s the deal with these weatherproofed buildings? Let’s see why farmers nationwide are getting excited.

What Makes a Building Weather-Resistant?

First off, what exactly does it mean for a building to be “weather-resistant”? Well, simply put, it’s about using the right materials and designs that can withstand things like:

- Heavy snow in the winter

- Strong winds and rain

- Extreme temperature changes

The weather in Canada is unpredictable. You can be dealing with a lot of snow one day, and then freezing rain or severe winds the next. Therefore, your buildings must be durable enough to withstand all of that without requiring frequent repairs if you own a farm or any other type of agricultural setting.

For this reason, your buildings need:

- Durability: Tough materials that don’t rust, rot, or crumble under weather’s assault.

- Insulation: Keeps things cozy inside, benefiting both animals and your bottom line.

- Weatherproofing: No leaks! Tight seals and water-repelling finishes keep everything dry.

- Strength: Built tough to handle heavy snow, gale-force winds, and wild temperature swings.

Whether it’s your agricultural barn, a grain storage facility, or equipment shed, you need a structure that can stand the test of time and the weather.

The Benefits of Weather-Resistant Agricultural Buildings

Let’s go over the advantages of weather-resistant agricultural structures:

- Protection Against Harsh Winters

Canadian winters? Brutal. They can wreck buildings in no time.

Enter resilient designs. Steel-framed and fabric-covered buildings are great. Snow just slides right off. Arch-shaped buildings are even better. Their curves are natural at the snow-shedding game, especially in places like Alberta and Manitoba.

Bottom line: weather-resistant materials prevent cave-ins and keep moisture damage at bay.

- Defending Against Summer Heat and Storms

Let’s not forget summer. With the heat, humidity, and sometimes crazy storms, your barn can take a beating. But climate-resilient buildings, like the ones we’re talking about here, actually help with temperature control.

Special UV-resistant fabric blocks heat, protects against sun damage, and helps maximize profits. Plus, that fabric lets in tons of natural light, cutting down on the need for electric lights.

And those summer downpours? Weather-resistant barns are built to keep the water outside where it belongs.

- Efficient Climate Control

If you’re storing hay, grain, or livestock, keeping temperatures steady is crucial.

Fabric buildings really excel here, improving efficiency. They don’t soak up heat like metal or trap moisture like concrete, so they stay cooler in summer and warmer in winter.

Thanks to weather-resistant construction, you get a productive environment all year round.

How Prefabricated Buildings Improve Weather Resistance

Want a building that’s guaranteed to stand up to the elements? Go after prefabricated buildings. These are engineered indoors, then assembled on your site, helping maximize farm efficiency through these prefabricated building solutions.

- Faster Assembly: Saves time getting things up and running.

- Stronger Materials: These buildings are tough. The materials used are designed for the long haul, meaning you won’t have to worry about replacing things every few years.

- Customizable Design: Arch or peak? Pick what fits your needs: arch for snow country, peak-shaped buildings for extra headroom.

Not sure which is right for you? If you’re still wondering what the differences are between the shapes and designs, check out this post comparing arch-shaped vs. peak-shaped buildings

Extending Your Barn’s Lifespan

Durable structures are built to last. A well-designed, weather-resistant farm building can easily last 30 years or more!

Some tips to extend your barn’s lifespan:

- Regular Maintenance: Check for wear and tear after each season.

- Ventilation: Good airflow prevents condensation and moisture buildup.

- Repairs: Fix small problems before they become big headaches.

Seasonal Tips for Maintaining Your Farm Building

Every season throws something different at your buildings. Here are seasonal tips for maintaining farm buildings:

- Winter: Clear heavy snow off roofs, and seal up any leaks.

- Spring: Inspect for winter damage, make sure everything’s watertight, and clear out drainage.

- Summer: Watch for UV damage to the fabric; keep the air flowing.

- Fall: Inspect for moisture damage, and prepare for winter’s worst.

Stay on top of these, and you’ll add years to your building’s life.

Fabric Buildings for BC Farmers: An Ideal Solution

Fabric buildings improve airflow and handle both rain and snow with ease. They’re versatile, affordable, and built to endure.

Fabric buildings are perfect for BC farmers, offering:

- Affordable & Low Maintenance: Cheaper to build and maintain than traditional barns.

- Quick Setup: Erected in just weeks, minimizing downtime.

- Weather-Resilient: Built to withstand heavy snow, high winds, and moisture.

- Natural Light: Saves on energy with bright, diffused daylight.

- Great for Livestock & Crops: Healthy, productive environment and prevents mould/spoilage.

- Temperature Control: Cooler in summer, warmer in winter, no HVAC needed.

- Maximized Space: Clear-span design for easy movement of large equipment.

- Flexible & Expandable: Easy to modify or relocate as your needs change.

Fabric buildings are only getting better. Count on designs that are even more energy-efficient and weather-resistant in the coming years. Think solar panels, better insulation, and sustainable materials, all helping farmers shrink their carbon footprint and slash their expenses.

Your building is a major investment. But don’t fixate on price tags; focus on the long game alongside farm efficiency. Weather-resistant structures save you money on maintenance, protect what’s inside, and let you sleep better at night. Building solutions for agriculture will invest peace of mind; think commercial, industrial, and personal storage.

If you’re thinking about upgrading your farm buildings, take a look at how to install fabric buildings or explore more about the future of fabric buildings.

Why Pre-Fabricated Buildings Are the Future of Construction

If you have ever worked on a construction project, you are aware of how messy, costly, and time-consuming it can be. There are many issues, including labor shortages, weather delays, and rapidly rising material costs. For this reason, a large number of Canadian builders, developers, and entrepreneurs are beginning to use prefabricated construction.

So, why is prefabrication in building gaining ground? Let’s talk about it, with a mix of real insights and practical examples.

What Exactly Is Prefabrication?

Prefabrication (or prefabricated construction) means that most parts of a building, like walls, trusses, beams, and sometimes entire sections, are built off-site in a controlled factory environment. Once they’re ready, these components are transported to the site and assembled like high-quality building blocks.

This is a world away from traditional builds, where you’re literally building from the ground up, on the spot. Across Canada, and I mean from those windy farms in Saskatchewan to busy commercial hubs in bigger cities, prefab construction is becoming the go-to choice for people who need things done right, done fast, and without breaking the bank.

Why Prefabricated Buildings Are Changing the Game

Let’s explore why prefabricated buildings are the future:

1. Faster Timelines, Lower Costs

If you’ve ever managed a construction timeline, you know the frustration of waiting weeks for one trade to finish before the next can start. Because the main structure is built indoors, the schedule is predictable. You can work on-site preparation and manufacturing simultaneously, which saves weeks or even months. By the time your foundation is ready, the building components are too.

This overlap explains why prefabricated buildings save time and reduce costs; you’re not waiting on deliveries or dealing with weather delays that can drag a project through multiple seasons.

And the savings are not just about time. You also cut costs in material waste, labour, and site management.

Many businesses switch to prefabricated building solutions because the overall “real cost of building solutions,” not just the sticker price, ends up being much lower.

2. Built Stronger and Smarter

Modern steel frames, insulated panels, and durable fabric coverings are built like tanks. They’re designed to handle whatever Canada throws at them, like blizzards, scorching summers, you name it. And because these components are made in a controlled environment, quality is a priority. That’s why prefabricated construction tends to be more robust.

Plus, prefab designs today are far more customizable than before. You can choose between arch-shaped buildings, peak-shaped buildings, or even hybrid structures, depending on your space, function, and design preference. If you’re curious about which is better, take a look at arch-shaped vs. peak-shaped buildings; both have their strengths, but the best one depends on your needs.

3. Environmentally Responsible Choice

Sustainability is another reason prefabrication in construction is booming.

Because prefab parts are made in a factory, material waste is tightly controlled, and every cut and weld is optimized. These facilities often recycle scrap materials and use energy-efficient processes.

Transportation is also minimized since components are delivered in fewer, consolidated shipments. And once the structure is up, prefab buildings are easy to disassemble or expand, making them a more sustainable long-term solution than rigid concrete or wood builds.

For industries looking to reduce their carbon footprint, prefab is a win-win, greener, cleaner, and future-ready.

4. Adaptable to Every Industry

One of the most impressive things about prefab buildings is their versatility. Let’s break down how different sectors across Canada are using them:

Agriculture

Farmers are loving building solutions for agriculture because they’re up fast, handle the weather, and don’t need constant fixing. Arch-shaped buildings with fabric are favorites for keeping animals safe, storing hay, and protecting equipment. They’re light, and they have huge spaces to move around.

Commercial and Industrial

From regular commercial buildings to heavy-duty industrial buildings where they’re moving boxes around, prefab is a top call for companies that need sturdy places and they need them fast. You can customize them to have offices, workshops, and even production lines.

Municipal Solutions

You’ll see municipal solutions made with prefabricated building materials in towns across Canada. Transit garages, public works places, and recreation centers are being erected more easily. They can even get them in place during the off-season.

Personal and Private Storage

Prefabricated construction isn’t just for big companies. People want personal storage they can pay for, in the form of prefab kits they can assemble themselves. They’re up quickly and fit right in, whether it’s a small shed or something to keep their RV safe.

5. Modular Building Renovations

Instead of tearing down and starting over, companies are deciding to upgrade existing prefab buildings by adding new spaces.

For example, a business can add a new warehouse on the side and keep going. It’s a great idea for businesses that want to grow.

6. Easy to Install

One of the biggest advantages of prefabrication is how streamlined the entire process is from design to installation.

It usually follows these stages:

- Consultation & Design: You discuss your needs, building size, and intended use. Engineers design the structure using digital models.

- Manufacturing: Components are fabricated in a climate-controlled facility, ensuring precision and quality.

- Site Preparation: At the same time, your site is graded, and the foundation is poured.

- Delivery & Installation: Once ready, the prefab parts are shipped to your site. Skilled installers can assemble the entire building in days or weeks, far faster than traditional construction timelines.

If you’re curious about this part, here’s a guide on how to install fabric buildings; it gives a good sense of just how simple modern prefab systems have become.

7. The Real Cost Advantage

People talk about paying for prefabricated buildings, but it’s more than that. You get lower labor costs, less wasted materials, speedier build-out, and affordable maintenance.

These savings add up.

The real cost of building solutions is both affordable upfront and savings down the road.

What the Future Holds

Looking ahead, experts predict that prefabricated construction will dominate the market within the next decade. Technological advances like 3D printing, AI-driven design, and robotics are taking prefab innovation to the next level.

We’ll see smarter insulation systems, stronger lightweight materials, and more energy-efficient prefab buildings that are both eco-friendly and budget-friendly.

Expect better insulation and stronger materials. The future of fabric buildings is looking bright as Canada has more and more companies using them. Browse our prefabricated buildings and find one for your firm.

Why Businesses Are Switching to Prefabricated Building Solutions

If you’ve been in business long enough, whether in agriculture, logistics, manufacturing, or construction, you’ve probably noticed a major shift happening in how companies build. Gone are the days when every new warehouse, barn, or facility meant months of concrete pouring and steel welding. Today, more and more Canadian businesses are turning to prefabricated building solutions, especially fabric buildings, and for good reason.

Let’s take a closer look at why this trend is taking over Canada’s commercial and industrial landscape and what makes these modern structures such a smart investment.

1. Businesses Need to Build Smarter, Not Slower

Whether you’re housing heavy equipment, storing materials, or expanding operations, every extra week of construction means lost productivity.

That’s where fabric buildings for businesses come in. They’re pre-engineered, manufactured off-site, and assembled on your property in a fraction of the time it takes to build traditional structures.

A project that could take months with steel or concrete often takes just a few weeks with prefabrication. This means:

- Faster turnaround times.

- Earlier occupancy.

- Less weather-related delay (a big plus in Canadian winters!).

Companies like SpanMaster have perfected this from the design to the installation process, ensuring that businesses can get operational faster without cutting corners on quality or safety.

2. Lower Costs Without Lowering Standards

Let’s be real, one of the first questions any business asks is, “How much will this cost me?”

Traditional building projects often come with hidden costs, including extended labour hours, material waste, long permit processes, and maintenance headaches down the road.

With prefabricated building solutions, you’re not just saving on materials; you’re cutting costs across the board.

Here’s how:

- Material Efficiency: The components are engineered and cut precisely before arriving on-site, meaning little to no waste.

- Faster Installation: Fewer labour hours and equipment rentals mean major cost savings.

- Low Maintenance: Fabric membranes don’t rust, rot, or peel, and the galvanized steel frames are corrosion-resistant.

- Energy Savings: The translucent fabric naturally lets in light, reducing electricity costs for lighting.

So when you look at the real cost of building solutions, fabric structures often come out on top, not just cheaper upfront but smarter in the long run.

3. Strength and Durability That Match Canada’s Climate

Canada’s weather can be unpredictable, with heavy snow in Alberta, wind gusts in Saskatchewan, and freezing rain in Ontario. Businesses here can’t afford to gamble on a building that won’t hold up.

Modern fabric buildings are engineered to handle it all. The steel frames are built for high snow and wind loads, and the fabric membranes are UV-protected, waterproof, and flexible enough to expand and contract with temperature changes.

Depending on your needs, you can choose between:

- Arch-Shaped Buildings: Ideal for snow shedding and lower material costs.

- Peak-Shaped Buildings: Provide greater interior clearance for large equipment.

If you’re not sure which one’s right for you, check out this guide comparing arch-shaped vs. peak-shaped buildings. It’ll help you pick the best fit based on your business type and region.

4. Flexibility for Every Industry

One of the biggest advantages of buildings for businesses made with prefabrication is their flexibility.

These aren’t just for farms or storage anymore. They’re now used across multiple industries:

- Building Solutions For Agriculture: For hay, grain, or equipment storage, fabric buildings also make excellent livestock shelters.

- Industrial Buildings: Warehousing, manufacturing, and logistics companies love them for their open-span interiors that allow easy machinery movement.

- Commercial Buildings: Car dealerships, equipment rental companies, and garden centres use them as showrooms or storage areas.

- Municipal Solutions: Perfect for salt and sand storage, waste management, or public works facilities.

- Personal Storage: From RV shelters to private workshops, they’re affordable, attractive, and functional.

You can even customize them with doors, ventilation systems, insulation, and solar panels, proving that “prefabricated” doesn’t mean “basic.”

5. Quick, Clean Installation

If you’ve ever been through a traditional construction project, you know the chaos and weeks of noise, dust, and disruption. Prefabricated buildings are a totally different experience.

The fabric building installation process is fast and clean. Once your foundation or anchoring system is ready, crews can assemble and stretch the fabric cover in just days. There’s minimal waste, no wet concrete curing delays, and no constant equipment clogging up your site.

This efficiency is why many companies with active sites, like farms, distribution centres, and municipalities, choose fabric structures. They can keep operating while construction happens nearby.

You can learn more about the steps in how to install fabric buildings.

6. Sustainability That Pays Off

Environmental responsibility isn’t just a buzzword anymore; it’s becoming a business requirement.

Fabric buildings align perfectly with Canada’s growing focus on sustainable construction because:

- The materials are recyclable.

- Construction produces less waste.

- Natural lighting reduces electricity use.

- Their lightweight design means smaller foundations, which use less concrete and steel.

Over time, that also means lower operating costs and a smaller carbon footprint, two things every environmentally conscious business wants to achieve.

7. Long-Term Value and ROI

Businesses aren’t switching to prefabricated buildings just for short-term savings; they’re thinking about longevity.

Modern fabric buildings for businesses can last 20-25 years with minimal maintenance. The hot-dip galvanized steel structure resists corrosion for decades, and the fabric cover can easily be replaced or repaired at a low cost if needed.

This long lifespan, combined with lower upkeep and operating costs, means an excellent return on investment. And if your operations expand, these structures can be relocated or extended with ease, something you can’t say about concrete or brick buildings.

That’s why prefabricated building solutions are the future; they’re not just an alternative, they’re an upgrade.

8. Canada’s Future Is Prefabricated

As more Canadian industries modernize, speed and adaptability are becoming essential. Prefabrication helps businesses stay agile, whether they’re building for growth, sustainability, or cost control.

The future of fabric buildings is bright, with more integration of smart tech, renewable energy options, and advanced insulation. For many companies, switching to prefabrication isn’t just about keeping up: it’s about staying ahead.

Whether you’re a farmer adding new storage, an industrial operator expanding production, or a municipality upgrading infrastructure, prefabricated fabric buildings are proving to be the most practical and cost-effective solution.

They’re fast, strong, eco-friendly, and built for Canadian conditions. And beyond the numbers, they make business sense, giving you flexibility and reliability without the headaches of traditional construction.

If you’re ready to explore the next generation of building solutions for businesses, contact us.

How Industrial Businesses Can Reduce Costs with Sustainable Structures

Are rising operational costs squeezing your business? To stay competitive, it’s critical to find ways to trim expenses. Imagine cutting costs and shrinking your environmental footprint. Start exploring how industrial operations can reduce costs with sustainable structures.

It’s about making sound, fiscally responsible decisions that benefit your bottom line. Let’s dive into how sustainable buildings can drastically lower expenses, boost efficiency, and elevate your brand. And we’ll explore options such as fabric-covered vs traditional buildings.

Understanding Sustainable Building: The New Standard

Sustainable building is no longer a niche idea. It’s about designing, constructing, and operating buildings in a way that minimizes environmental impact, from material selection, to energy use.

Think of it this way: a traditional building can be like an energy-guzzling machine, expensive to run and hard on the environment. A sustainable building, in contrast, can be more like a hybrid vehicle – efficient and eco-friendly.

Advantages of Sustainable Structures:

- Reduced Energy Consumption: Green architecture utilizes natural light and airflow, which leads to less need for artificial heating and lighting.

- Lower Operational Costs: Significant long-term savings can come from reduced energy bills and lower maintenance through sustainable buildings.

- Enhanced Employee Productivity: Happier employees in sustainable buildings seem to show up more and achieve more.

- Improved Brand Image: Show your customers you care with a sustainable building, since they prefer to buy from eco-conscious businesses.

Fabric Buildings: Economical and Environmentally Sound

While conventional sustainable building offers benefits, building can often be time-consuming and expensive. That’s where fabric structures come in. These modern industrial buildings offer a blend of affordability, adaptability, and environmental performance.

Why Choose Fabric Buildings?

- Lower Construction Costs: Simpler frames coupled with tensioned fabric membranes mean faster construction and lower labor costs compared to traditional construction. Allowing your commercial buildings or industrial buildings to be up and running sooner.

- Energy Efficiency: Translucent fabric lets in plenty of natural light, which reduces the need for artificial lighting– and slashes energy usage.

- Durability and Longevity: Quality fabrics stand up to harsh weather for years with minimal upkeep.

- Adaptability: Relocate or expand fabric buildings easily, helping businesses adapt and grow. Making them especially useful as building solutions for agriculture, agricultural storages, municipal solutions, or even personal storage.

- Sustainability: Reduced waste during manufacturing, natural lighting, and long-lasting materials reduce environmental impact, making them a sustainable build.

Arch Shape Buildings vs. Peak Shape Buildings

Fabric buildings come in various forms, primarily arch shape buildings and peak shape buildings, which can be set up on either fixed or temporary foundations. The shape and design are critical for structural integrity, alongside other design benefits. Consult experienced engineers to choose the best design for your needs.

Practical Steps to Embrace Sustainable Structures

Eager to capitalize on the cost-saving potential of sustainable structures? Here’s how to get started:

- Assess Your Needs: Pinpoint your facility needs upfront. Do you need a warehouse? A production location? A storage space?

- Consider Fabric Buildings: See whether fabric structures are the right investment. Their affordability and limited footprint make them an attractive option. Also begin planning how to install fabric buildings according to your requirements.

- Partner with Experts: Get advice from experts specializing in sustainable building design and construction. They can suggest excellent products, identify energy efficiency measures, and ensure all environmental requirements are met.

- Explore Grants and Incentives: Find grants available to businesses who invest in sustainable initiatives. These funds can significantly lower your initial costs.

The Future of Fabric Buildings is Bright

There is a bright future of fabric buildings since there is increasing interest in environmentally friendly options. Thanks to ongoing innovations in materials and construction, count on more affordable and higher-performing fabric structures. Let’s make sustainability building a priority today.

Sustainable structures help protect the environment and let you reduce costs. Your bottom line and the planet both benefit from it.

Want to learn more about how sustainable buildings can help your business?

Get in touch with SpanMaster today!

Understanding the Real Cost and Value of Fabric Building Solutions

If you’ve ever started pricing out a new building project, whether it’s for storage, farming, or a municipal facility, you know how confusing it can get. One quote gives you a “base price,” another adds site prep, and before you know it, you’re knee-deep in spreadsheets trying to figure out what’s actually included.

That’s why more people across Canada are taking a closer look at fabric building solutions. You’ve probably heard about them: those bright, open-span structures covered in durable tensioned fabric. They’re everywhere now, from salt storage domes to airplane hangars.

But here’s the thing: when you hear numbers like “coverall building prices starting at $10 per square foot,” it doesn’t tell the full story. The real value of these buildings goes beyond the upfront cost. Let’s break it down: what you’re actually paying for, what affects the price, and why these buildings often deliver more value per dollar than traditional construction.

What Are Fabric Buildings and Why Are They So Popular in Canada?

A fabric-covered building is a steel-framed structure wrapped in a high-strength polyethylene or PVC fabric membrane. Unlike conventional buildings made from concrete, wood, or metal siding, these structures are lightweight, durable, and incredibly versatile.

In Canada, they’re used for everything from agriculture and industrial buildings to municipal solutions like salt and sand storage. Homeowners also use smaller versions for personal storage, like garages, workshops, or recreational spaces.

The appeal? They’re quick to install, built to handle Canadian weather, and cost significantly less than traditional buildings. But let’s talk specifics.

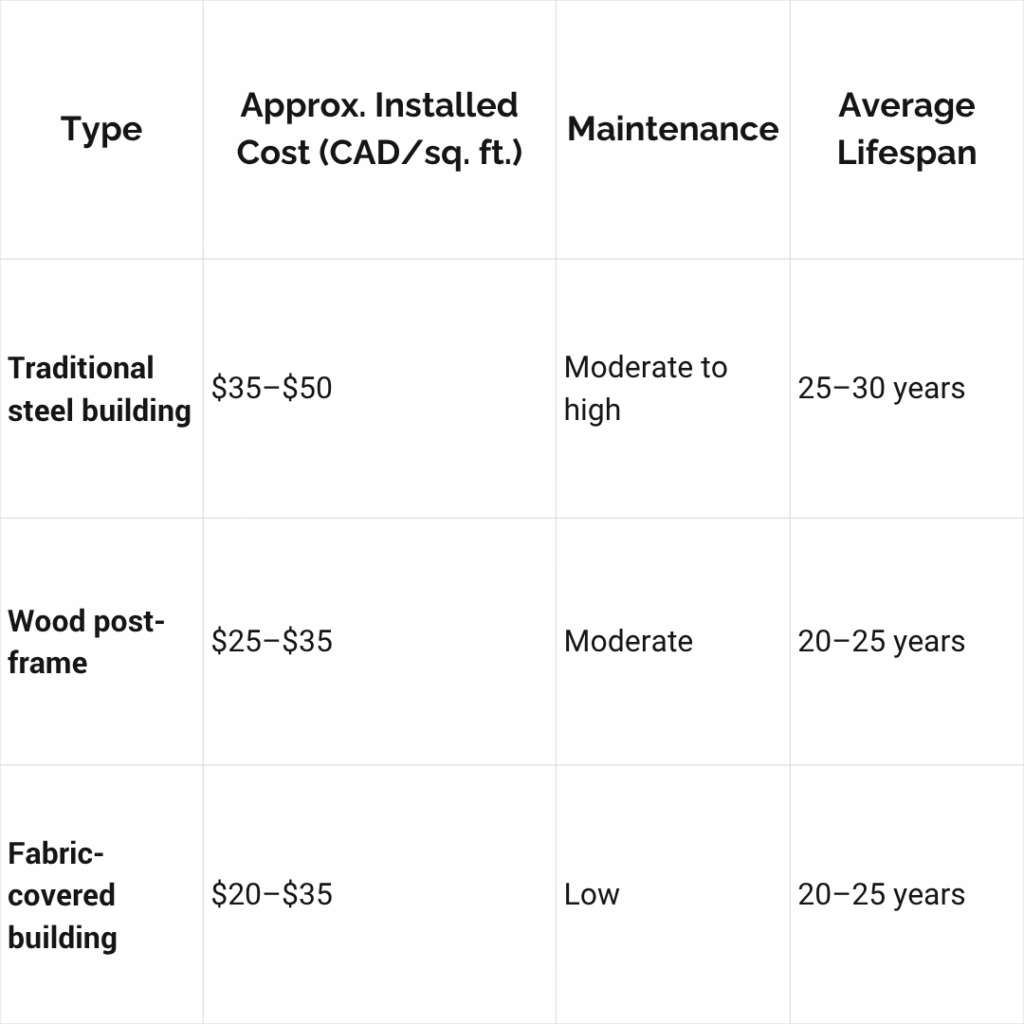

The Average Cost of Fabric Buildings in Canada

If you’re just starting your research, you might search for fabric building prices or coverall building prices in Canada and see a wide range, anywhere from $20 to $35 per square foot.

That’s because several factors affect the final price, including:

1. Size and Design

Larger buildings generally cost less per square foot but more overall. You’ll also need to decide between arch-shaped buildings (great for snow load and lower cost) or peak-shaped buildings (ideal for extra clearance and a more traditional look). Not sure which one to choose? Here’s a good comparison of arch-shaped vs. peak-shaped buildings.

2. Foundation Type

Your site prep can make a huge difference. A simple helical anchor foundation is more affordable than a full concrete pad. But if you’re planning to use heavy equipment or need permanent flooring, concrete might be worth the investment.

3. Frame and Fabric Quality

Heavier-duty steel and thicker fabric membranes come at a higher cost but can extend your building’s lifespan and warranty. For Canadian climates, most experts recommend 12.5 oz or 14.5 oz fabric covers designed to resist UV rays, snow, and wind.

4. Installation and Location

Costs can vary depending on your province, local labour rates, and how remote your site is. The good news? Most fabric building installation projects take only a few days to a few weeks, which saves a ton in labour compared to traditional builds.

5. Accessories and Customization

Adding doors, ventilation, insulation, or lighting increases the total cost but also enhances usability.

When you add everything together, including materials, labour, maintenance, electricity, and ventilation, fabric buildings consistently come out ahead in total cost and value.

Here’s a quick snapshot:

The “Hidden” Savings That Make Fabric Buildings Worth It

Here’s where things get interesting. While the fabric-covered building’s cost might look similar to or slightly less than a steel building at first glance, you’ll start saving money right after construction.

1. Faster Construction = Lower Labour Costs

Because components are prefabricated, the building construction phase is shorter. That means you save not just on labour but also on financing, and you’re up and running faster. (Check out our blog on how prefabricated buildings save time and reduce costs for a closer look.)

2. Minimal Maintenance

The fabric membranes used today are incredibly durable. They don’t rust, peel, or require painting. Unlike metal roofs that corrode or wooden walls that rot, a fabric building can last 20–25 years with minimal upkeep.

3. Natural Lighting

One of the most underrated benefits is how the fabric allows sunlight to pass through, creating a bright interior without the need for daytime lighting. Over time, that means lower energy bills.

4. Flexibility and Relocability

Many SpanMaster-style buildings are designed to be portable. If your business relocates or expands, you can move your structure, something you definitely can’t do with traditional construction.

5. Weather Performance

The high-tensile fabric and galvanized steel framing make these structures incredibly resilient against snow, wind, and moisture. Especially in Canadian winters, the arch shape of the roof naturally sheds snow and prevents accumulation.

Beyond the Price Tag: The Long-Term Value

When you’re evaluating coverall building prices, it’s easy to focus on the initial number. But think about the total cost of ownership, the combination of purchase, maintenance, operation, and lifespan.

Let’s say you’re comparing a 10,000 sq. ft. storage building:

Even if the initial cost is similar on paper, your fabric building wins in the long run thanks to lower energy use, faster construction, and reduced maintenance.

That’s where the real value of fabric buildings comes in, not just what you pay, but how much value they deliver over time.

From Design to Installation: Transparency in Every Step

One thing that sets companies like SpanMaster apart is how clearly they walk you through the process. From design consultation to installation, you’ll know exactly what’s included and what’s optional.

The design-to-installation typically includes:

- Initial consultation: Define use, size, and site conditions.

- Engineering and design: Choose between arch or peak design, insulation options, and foundation type.

- Prefabrication and shipping: Everything is built in a controlled environment for precision.

- On-site installation: Crews assemble the frame and stretch the fabric cover in just days.

By the time your structure is up, you’ve already saved weeks or months compared to a traditional build, without sacrificing strength or quality. You can check out an even more detailed guide on how to install fabric buildings.

Why Switch to Fabric Building Solutions

Across Canada, businesses switch to prefabricated building solutions for one simple reason: they make financial sense.

Farmers use them for building solutions for agriculture, including hay, grain, or livestock shelters. Manufacturers and logistics companies rely on them for industrial and commercial buildings. buildings that require wide-open interiors. Municipalities love them for salt and sand storage and even emergency response shelters.

The versatility means one design can fit multiple uses, and when you consider how building solutions are the future, the decision gets even easier.

Are Fabric Buildings the Future in Canada

With rising construction costs and sustainability demands, prefabricated building solutions are the future. Modern designs now incorporate solar panels, high-efficiency insulation, and automated ventilation systems.

SpanMaster and other leading Canadian manufacturers are investing in innovation to make these structures even more energy-efficient and environmentally friendly, a big plus for businesses aiming to reduce their carbon footprint.

Final Thoughts: Cost vs. Value

Here’s the takeaway:

- Coverall building prices might vary, but the value you get from a well-designed, properly installed fabric building is unbeatable.

- You’re paying for more than a structure; you’re investing in durability, flexibility, and long-term savings.

- And when you compare the full lifecycle: design, installation, operation, and maintenance, these buildings often outperform traditional options by a mile.

So, if you’re still wondering whether a fabric building is worth the cost, the answer is yes, as long as you choose a trusted company that guides you through every phase and tailors the design to your needs.

Ready to explore your options? Learn more about arch-shaped buildings and peak-shaped buildings, or read about why prefabricated buildings save time and reduce costs. Whatever your next project looks like, a fabric building solution might just be the smartest investment you’ll make.

From Design to Installation: What to Expect When Building with SpanMaster

So, you’ve been thinking about adding a new structure, maybe a workshop, farm shelter, or storage building, and you keep hearing that SpanMaster is the way to go. You’re not wrong. When it comes to prefabricated building construction, SpanMaster has built a solid reputation in Canada for creating reliable, durable, and flexible fabric-covered buildings that actually make sense for our climate and business needs.

But what’s the process really like, from the moment you say “let’s do it” to the day you walk inside your new building? Let’s go through it together, step by step.

1. The Vision Stage: Turning an Idea into a Plan

Every project starts with a need. Maybe your agricultural operation is growing, and you need more space for equipment or livestock. Maybe your industrial facility is expanding. Or maybe you just want a durable personal storage solution that can handle Canadian winters.

At this stage, you’ll sit down (often virtually) with the SpanMaster design team to talk about what you want, not just size and shape, but also purpose. This is where the design of a building really takes shape.

A few questions will help you:

- What will the building be used for: storage, production, or livestock housing?

- Do you prefer arch-shaped buildings (great for snow shedding) or peak-shaped buildings (perfect for extra headroom)?

- What kind of foundation suits your site best: concrete, helical anchors, or portable options?

This phase is exciting because you start to see the big picture, and SpanMaster helps make sure your expectations align with engineering realities.

2. The Design Phase: Where Function Meets Form

Once your goals are clear, SpanMaster’s engineers get to work. They’ll prepare fabric-covered building design considerations tailored to your needs and environment. This is not an one-size-fits-all process; each structure is engineered for durability, snow load, and wind conditions specific to your region in Canada.

Here’s what typically happens during the building design and installation planning stage:

- Site Analysis: Soil type, slope, drainage, and access points are evaluated.

- Structural Design: The team models your frame system and fabric covering for optimal strength and light diffusion.

- Permitting Guidance: You’ll receive stamped engineering drawings that comply with local building codes, which simplifies permit applications.

- Budget Planning: You get a clear breakdown so there are no surprises; the real cost of building solutions is transparent right from the start.

This stage defines the efficiency and performance of your future building. It’s also where SpanMaster’s experience in prefabrication in construction shines.

3. Prefabrication: The Power of Building Smart

Before anything is shipped to your site, every component of your building, from steel trusses to tensioned fabric panels, is fabricated in a controlled environment.

This prefabricated building process ensures consistent quality and fast assembly once materials arrive. It’s the same principle behind why a prefab home in Ontario can be completed faster and more affordably than a traditional house construction project.

So, what is prefabrication in construction exactly? In simple terms, it means the building parts are made off-site, inspected for quality, and then delivered ready to assemble. This reduces construction time, labour costs, and material waste—three things every Canadian project manager appreciates.

SpanMaster’s use of prefabrication is one reason so many businesses switch to prefabricated building solutions each year. It’s smarter, cleaner, and faster.

4. The Construction Phase: From Groundwork to Installation

Now comes the part everyone looks forward to: seeing your building come to life. The building construction phases with SpanMaster are organized and efficient.

- Site Preparation: This step involves clearing, leveling, and preparing your site. Depending on your project, a concrete pad, footings, or anchors are installed.

- Frame Installation: The pre-engineered steel frames are erected and secured to the foundation. Because every piece is pre-cut and pre-drilled, the assembly process is smooth and much faster than a typical home construction project.

- Fabric Installation: This is where things start looking impressive. The high-tension fabric cover is stretched over the frame, secured, and tightened using specialized tools. The result? A seamless, weather-resistant exterior that diffuses natural light beautifully and holds up in even the toughest climates.

SpanMaster crews are experts in fabric building installation, meaning you’ll get a precise, professional finish without the delays that plague traditional construction.

5. Final Inspection and Handover

Once installation is complete, the team conducts a detailed inspection to ensure everything meets structural, safety, and design standards. They’ll also walk you through maintenance steps, though, to be honest, there’s not much upkeep involved.

Within weeks, you’ll have a fully functional fabric-covered building ready to use, whether it’s for storage, agriculture, or commercial operations.

It’s amazing how quick and seamless the process is compared to old-school building methods. If you’re curious about the difference in timelines, check out how prefabricated buildings save time and reduce costs compared to conventional construction.

6. Beyond Installation: A Long-Term Investment

What makes SpanMaster stand out is that their relationship with clients doesn’t end once the building is installed. They offer ongoing support, from expansion options to maintenance advice.

Because their buildings are modular, you can expand or relocate them easily as your business evolves. This is especially valuable for growing industrial buildings or seasonal municipal solutions that may change in size or purpose over time.

You’re not just buying a building; you’re investing in flexibility. And in today’s economy, that’s priceless.

7. Why SpanMaster Works for Canadian Conditions

Let’s be honest, Canada’s weather can be brutal. Between heavy snowfalls in Alberta and high humidity in Ontario, not every structure can handle the challenge. SpanMaster buildings are engineered specifically for Canadian codes and climates.

Arch-shaped buildings are ideal for regions with heavy snow, as their curved design naturally sheds buildup. Peak-shaped buildings, on the other hand, provide excellent clearance for large equipment or vehicles. If you’re unsure which is right for you, here’s a quick comparison of arch-shaped vs peak-shaped buildings to help you decide.

These design options ensure your structure performs year-round while maintaining a professional look.

8. How Prefabricated Building Solutions Are Shaping the Future

Across Canada, we’re seeing a major shift toward efficient, sustainable building methods. The prefabricated building industry continues to grow because it meets modern demands and offers quick installation, durability, and minimal maintenance.

For farmers, manufacturers, and municipalities, prefabricated building solutions are the future. They cut project timelines, reduce carbon impact, and deliver long-lasting value. If you’re in agriculture, check out SpanMaster’s building solutions for agriculture; for others, we also offer designs for:

As materials and design technologies evolve, the future of fabric buildings looks even more promising. Expect stronger fabrics, more efficient insulation options, and integration with smart monitoring systems that track humidity, light, and internal temperature. SpanMaster continues to innovate in this space, ensuring every project delivers long-term performance, no matter where in Canada it’s built.

So if you’ve been thinking about starting a prefabricated building construction project, now’s the perfect time to explore your options. You’ll be amazed at how much faster and more cost-effective it can be when you build with SpanMaster. Request a quote today!

How Prefabricated Fabric Buildings Save Time and Reduce Construction Costs

If you’ve ever managed a construction project in Canada, you know how unpredictable things can get. One minute, you’re planning concrete pours, and the next, a snowstorm shuts everything down. That’s one of the big reasons more people are switching to prefabricated fabric buildings. They’re faster to build, easier on the wallet, and incredibly versatile for commercial, agricultural, and even municipal uses.

Let’s walk through how these buildings actually save time and money and why they’ve become such a smart move for Canadian businesses.

What Are Prefabricated Fabric Buildings?

A prefabricated building is essentially a steel frame structure covered with a high-strength tensioned fabric membrane. Instead of traditional materials like wood, brick, or concrete, these buildings rely on lightweight but durable components that are manufactured off-site, shipped to your location, and quickly assembled.

In Canada, you’ll often see them used for:

- Agriculture: Hay storage, livestock shelters, equipment covers

- Commercial and Industrial Uses: Warehousing, workshops, fleet storage

- Municipal Projects: Salt and sand storage, waste management facilities

- Personal Storage or Recreational Use: Garages, sports domes, or even backyard storage

Their flexibility is unmatched, ranging from compact personal storage to massive industrial setups; these structures can be designed for almost any purpose.

Why Prefabrication Changes the Game

The core advantage of prefabricated construction lies in how much of the process happens off-site. Every steel component, fabric panel, and connection point is pre-measured, pre-cut, and pre-engineered in a controlled environment.

That means once the materials arrive on-site, there’s minimal guesswork, and everything fits perfectly, like a large-scale Lego set. This drastically reduces time spent on installation and helps you avoid costly delays caused by weather or labour shortages.

In Canada, where construction seasons are short and conditions are often challenging, this efficiency makes a massive difference.

How Prefabricated Buildings Save Time

Now, let’s check out ways prefabricated buildings save time.

- Faster Project Turnaround

Since components are manufactured ahead of time, the on-site build is mostly about assembly, not cutting, welding, or pouring. A large-scale project that might take months with traditional methods can often be completed in just a few weeks with prefabrication.

- Minimal Weather Delays

Prefabrication keeps most of the work indoors, away from the unpredictable Canadian weather. By the time you’re ready to install on-site, all you need is a level base and a few good days to assemble the frame and attach the fabric cover.

- Streamlined Approvals and Design

Many companies offering prefabricated building solutions already have standard engineering drawings that meet provincial and municipal codes. This can speed up the approval process significantly compared to custom architectural designs.

- Simplified Installation

You don’t need a large team of specialized workers. In fact, with a trained crew and a telehandler, many fabric-covered buildings can be erected in a matter of days. (You can read more about this in our guide on how to install fabric buildings).

How Prefabricated Fabric Buildings Reduce Costs

Now let’s talk money, the part everyone cares about most.

- Lower Labour Costs

With less on-site work, you save big on labour hours. There’s no need for large teams of skilled trades or lengthy project supervision.

- Reduced Material Waste

Every component in a prefabricated building is measured and fabricated precisely before shipping. That means little to no waste, unlike traditional builds that often require cutting and adjustments on-site.

- Shorter Construction Loans

A faster build means your project is completed and generating value sooner. That also means less interest paid on construction financing and earlier occupancy for commercial or industrial tenants.

- Lower Maintenance

Fabric membranes are highly durable and resistant to corrosion, mould, and UV rays. This reduces long-term upkeep costs, especially when compared to metal or wood structures that require painting or repairs over time.

- Flexible and Expandable

Prefabricated structures can be relocated or expanded without major reconstruction costs, a major plus for growing agricultural and industrial businesses.

When you add it up, the prefab construction cost advantage can be substantial, often 20–40% less than conventional buildings, depending on size and complexity.

The Real Cost of Building Solutions

It’s easy to assume that prefabricated means “cheap,” but that’s not the case here. The real cost of building solutions lies in the total lifecycle, such as design, construction, operation, and maintenance. Pre-fabricated fabric buildings perform well across all these stages.

They’re not only cheaper to build; they’re also energy-efficient, require minimal lighting (thanks to natural light diffusion), and are eco-friendly to produce. This adds up to impressive savings over time, both financially and environmentally.

From Design to Installation: A Smoother Journey

When working with Canadian manufacturers, the design-to-installation process is seamless. You typically start with an initial consultation to determine size, shape, and function. Then, engineers customize the design, whether you need an arch-shaped building for snow load efficiency or a peak-shaped building for more interior clearance.

You can even compare the two (arch-shaped vs. peak-shaped buildings) to see which fits your application better. Once the design is finalized, components are fabricated, shipped, and assembled on your site.

The entire process is predictable, transparent, and faster than traditional construction, reducing stress for business owners managing multiple priorities.

Why Canadian Businesses Are Switching to Prefabricated Building Solutions

Across the country, businesses are switching to prefabricated building solutions because they fit modern demands, offer faster delivery, are sustainable, and are flexible.

Industries are evolving, and so are their building needs:

- Agriculture: Quick-to-install shelters for livestock or crop storage

- Commercial Buildings and Industrial Buildings: Durable warehouses and workshops

- Municipal Solutions: Cost-effective infrastructure like road salt storage

- Personal Storage: Backyard garages, carports, and recreational shelters

It’s no surprise that prefabricated building solutions are the future for Canada’s construction industry.

The Future of Fabric Buildings

As materials technology improves, the future of fabric buildings looks even brighter. Modern coatings and insulation systems allow these structures to perform well in extreme Canadian climates, from the Prairies to the Maritimes.

We’re seeing more hybrid solutions that combine prefabrication in the construction industry with renewable energy systems, such as solar panels or rainwater harvesting. This makes them not only affordable but also sustainable and environmentally responsible.

If you’re exploring prefabrication construction options, whether for a business, farm, or municipality, a fabric-covered building could be exactly what you need. They’re fast to build, cost-effective, and adaptable for almost any use, especially when compared to traditional concrete or steel structures.

In a country where time, weather, and cost all matter, prefabricated fabric buildings save time and reduce costs without compromising on quality.

Ready to explore your options? Browse our prefabricated buildings.