The popularity of tension fabric structures known as fabric buildings continues to rise in Canada because they offer flexibility, affordable prices, and fast deployment capabilities. The installation process for fabric buildings requires proper understanding because it determines both durability and functionality for agricultural storage and commercial and personal uses.

The following guide provides a detailed overview of tension fabric building installation procedures, together with essential best practices to help you complete a successful setup.

Understanding Tension Fabric Buildings

A sturdy frame made exclusively of hot-dip galvanized steel is encased in a long-lasting fabric membrane to form a tension fabric building. The fabric is tensioned over the frame to create a durable and weatherproof structure. These buildings are renowned for their strength, corrosion resistance, ease of assembly, and versatility, making them ideal for a wide range of uses, including industrial storage, personal applications, and agriculture.

Important advantages include:

- Cost-Effectiveness: Less expensive to build and maintain than conventional structures.

- Flexibility: Designs that can be altered to suit particular requirements.

- Durability: Able to withstand severe weather.

- Natural Lighting: By letting in natural light, translucent fabric lowers energy expenses.

Read our article on the future of fabric and steel structures to learn more about the benefits and upcoming advancements of these structures.

Pre-Installation Considerations

The fabric building installation requires several preparatory steps that need to be addressed before starting work.

- Site Assessment: The evaluation of the planned site must include assessments for soil stability, drainage, and accessibility. Check that your project meets all local zoning requirements before starting work and secure required authorization.

- Design Selection: Choose your preferred design between arch-shaped buildings and peak-shaped buildings according to your needs and visual preferences.

- Foundation Planning: The foundation selection process requires determination of concrete footings, ground anchors, or alternative systems based on soil conditions and intended building purpose.

- Climate Considerations: The structural integrity needs assessment should include local weather pattern analysis for snow loads and wind speeds.

Tools and Materials Required

A successful fabric building installation necessitates specific tools and materials:

Materials:

- Galvanized steel or aluminum frame components

- High-tensile fabric membrane (PVC or polyethylene)

- Anchoring systems (e.g., ground anchors, concrete footings)

Tools:

- Cranes or lifts for hoisting materials

- Hand tools (wrenches, hammers, etc.)

- Tensioning devices (ratchets, come-alongs)

- Safety equipment (helmets, harnesses, gloves)

All equipment needs to be in proper working condition while operated by trained personnel to uphold safety standards.

Step-by-Step Fabric Building Installation Process

Here’s a step-by-step guide on how to install a fabric building.

1. Site Preparation

Start by removing all debris, vegetation, and any other obstructions from the site. Level the ground and mark the layout according to the building’s specifications. The stability and longevity of the structure depend on proper site preparation.

2. Foundation Installation

The selected foundation system requires installation that must match both the building design and local building regulations. The foundation needs precise placement, together with secure anchoring systems, to resist environmental stresses.

3. Frame Assembly

The structural frame requires assembly through manufacturer-approved connections of steel or aluminum components. The placement of large sections requires crane or lift equipment for safe positioning. All connections must be checked for proper security and correct alignment.

4. Fabric Installation

Place the fabric membrane over the completed frame after unrolling it. The fabric needs to be stretched evenly using tensioning devices to achieve a tight fit while removing wrinkles. The building strength and appearance improve when tensioning is done correctly.

5. Final Adjustments and Inspection

A complete inspection should verify that all components are properly installed and tensioned. The structure should be checked for any indications of stress or misalignment. The structure requires adjustments to maintain both its performance and integrity.

Also check fabric-covered vs traditional buildings.

Tailored Building Solutions by Industry

Each industry requires unique structural needs, environmental requirements, and operational workflows for tension fabric buildings to serve their purpose. The following section explains how fabric building installation adjusts according to different industry requirements:

Agricultural Applications

The agricultural sector needs dependable, weather-resistant structures at affordable costs to shelter livestock and equipment, as well as feed supplies. The tension fabric structure design offers superior ventilation, natural lighting, and extensive open space that makes it ideal for barns and hay storage facilities and machinery shelters. Our building solutions for agriculture provide complete weather resistance and farm operational support for Canadian farms.

Commercial Use Cases

The fabric building market serves retailers, logistics companies, and event organizers who need temporary or semi-permanent spaces for inventory storage, showrooms, and seasonal operations. The buildings enable business flexibility through fast installation and branding options that support both business agility and growth. Our commercial buildings provide space solutions through efficient and quick deployment methods to support business expansion.

Industrial Applications

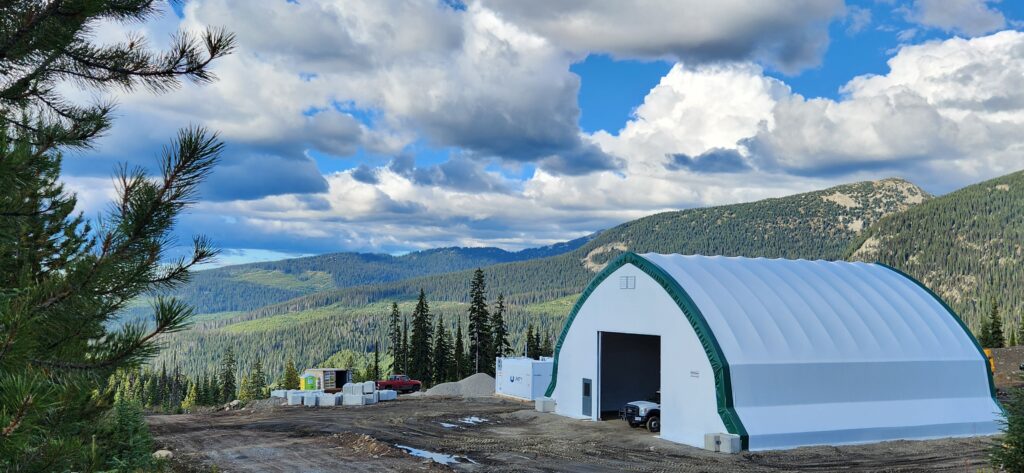

Industrial businesses, including mining, oil and gas, and manufacturing, benefit from tension fabric structures because they deploy quickly and scale up easily while meeting all necessary safety standards. The buildings function as equipment storage facilities and workshops and provide warehousing capacity. Our industrial buildings deliver customized high-performance solutions that meet the requirements of heavy-duty operations.

Your fabric building installation should match your industry requirements to achieve both immediate operational efficiency and extended product longevity.

Post-Installation Maintenance and Inspection

The longevity and functionality of tension fabric buildings depend on regular maintenance practices.

- Routine Inspections: The fabric should be inspected regularly for tears while checking the frame for corrosion and verifying the stability of anchoring systems.

- Cleaning: Any dirt and debris should be removed from the fabric surface to prevent degradation.

- Tension Adjustments: The fabric needs periodic re-tensioning because it will naturally lose its structural integrity over time.

- Component Replacement: The building’s safety depends on the immediate replacement of all worn or damaged parts.

Importance of Professional Installation

Professional installation provides multiple benefits to customers who choose this approach instead of doing it themselves.

- Expertise: The knowledge and experience of professionals enable them to complete complex installations with maximum efficiency.

- Compliance: The installation process follows all local building codes and safety regulations.

- Warranty Protection: Professional installation is often necessary for manufacturers to honour their warranty coverage.

- Time and Cost Efficiency: Professional installation services minimize the chance of mistakes that otherwise would require expensive repairs or cause project delays.

Professional services provide both peace of mind and long-term financial savings to customers.

The installation process of fabric buildings requires multiple steps that, when properly followed, lead to durable structures that serve multiple purposes. A successful project outcome depends on your understanding of site preparation through post-installation maintenance steps.

Our team is available to provide personalized solutions and expert guidance for your project requirements while discussing municipal solutions and personal storage options.

Some of our previous projects: