If you’ve ever started pricing out a new building project, whether it’s for storage, farming, or a municipal facility, you know how confusing it can get. One quote gives you a “base price,” another adds site prep, and before you know it, you’re knee-deep in spreadsheets trying to figure out what’s actually included.

That’s why more people across Canada are taking a closer look at fabric building solutions. You’ve probably heard about them: those bright, open-span structures covered in durable tensioned fabric. They’re everywhere now, from salt storage domes to airplane hangars.

But here’s the thing: when you hear numbers like “coverall building prices starting at $10 per square foot,” it doesn’t tell the full story. The real value of these buildings goes beyond the upfront cost. Let’s break it down: what you’re actually paying for, what affects the price, and why these buildings often deliver more value per dollar than traditional construction.

What Are Fabric Buildings and Why Are They So Popular in Canada?

A fabric-covered building is a steel-framed structure wrapped in a high-strength polyethylene or PVC fabric membrane. Unlike conventional buildings made from concrete, wood, or metal siding, these structures are lightweight, durable, and incredibly versatile.

In Canada, they’re used for everything from agriculture and industrial buildings to municipal solutions like salt and sand storage. Homeowners also use smaller versions for personal storage, like garages, workshops, or recreational spaces.

The appeal? They’re quick to install, built to handle Canadian weather, and cost significantly less than traditional buildings. But let’s talk specifics.

The Average Cost of Fabric Buildings in Canada

If you’re just starting your research, you might search for fabric building prices or coverall building prices in Canada and see a wide range, anywhere from $20 to $35 per square foot.

That’s because several factors affect the final price, including:

1. Size and Design

Larger buildings generally cost less per square foot but more overall. You’ll also need to decide between arch-shaped buildings (great for snow load and lower cost) or peak-shaped buildings (ideal for extra clearance and a more traditional look). Not sure which one to choose? Here’s a good comparison of arch-shaped vs. peak-shaped buildings.

2. Foundation Type

Your site prep can make a huge difference. A simple helical anchor foundation is more affordable than a full concrete pad. But if you’re planning to use heavy equipment or need permanent flooring, concrete might be worth the investment.

3. Frame and Fabric Quality

Heavier-duty steel and thicker fabric membranes come at a higher cost but can extend your building’s lifespan and warranty. For Canadian climates, most experts recommend 12.5 oz or 14.5 oz fabric covers designed to resist UV rays, snow, and wind.

4. Installation and Location

Costs can vary depending on your province, local labour rates, and how remote your site is. The good news? Most fabric building installation projects take only a few days to a few weeks, which saves a ton in labour compared to traditional builds.

5. Accessories and Customization

Adding doors, ventilation, insulation, or lighting increases the total cost but also enhances usability.

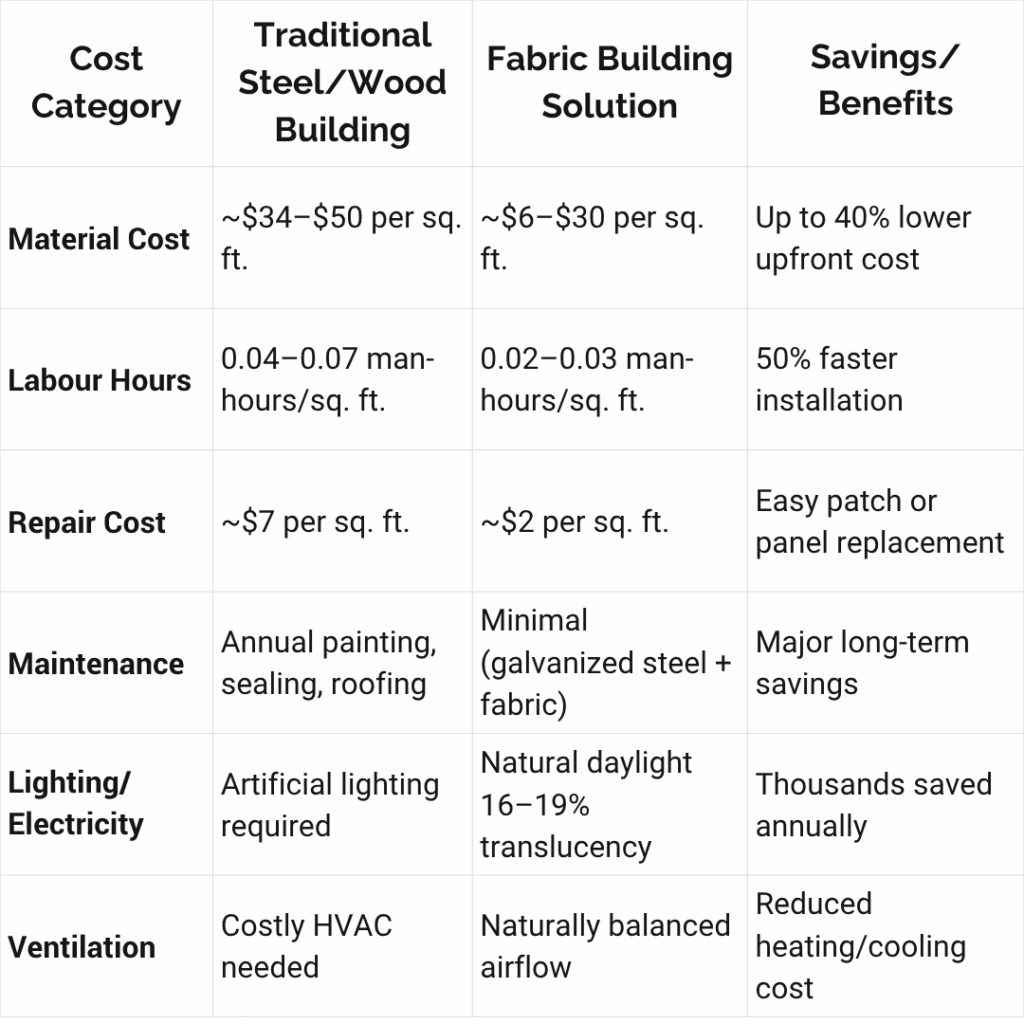

When you add everything together, including materials, labour, maintenance, electricity, and ventilation, fabric buildings consistently come out ahead in total cost and value.

Here’s a quick snapshot:

The “Hidden” Savings That Make Fabric Buildings Worth It

Here’s where things get interesting. While the fabric-covered building’s cost might look similar to or slightly less than a steel building at first glance, you’ll start saving money right after construction.

1. Faster Construction = Lower Labour Costs

Because components are prefabricated, the building construction phase is shorter. That means you save not just on labour but also on financing, and you’re up and running faster. (Check out our blog on how prefabricated buildings save time and reduce costs for a closer look.)

2. Minimal Maintenance

The fabric membranes used today are incredibly durable. They don’t rust, peel, or require painting. Unlike metal roofs that corrode or wooden walls that rot, a fabric building can last 20–25 years with minimal upkeep.

3. Natural Lighting

One of the most underrated benefits is how the fabric allows sunlight to pass through, creating a bright interior without the need for daytime lighting. Over time, that means lower energy bills.

4. Flexibility and Relocability

Many SpanMaster-style buildings are designed to be portable. If your business relocates or expands, you can move your structure, something you definitely can’t do with traditional construction.

5. Weather Performance

The high-tensile fabric and galvanized steel framing make these structures incredibly resilient against snow, wind, and moisture. Especially in Canadian winters, the arch shape of the roof naturally sheds snow and prevents accumulation.

Beyond the Price Tag: The Long-Term Value

When you’re evaluating coverall building prices, it’s easy to focus on the initial number. But think about the total cost of ownership, the combination of purchase, maintenance, operation, and lifespan.

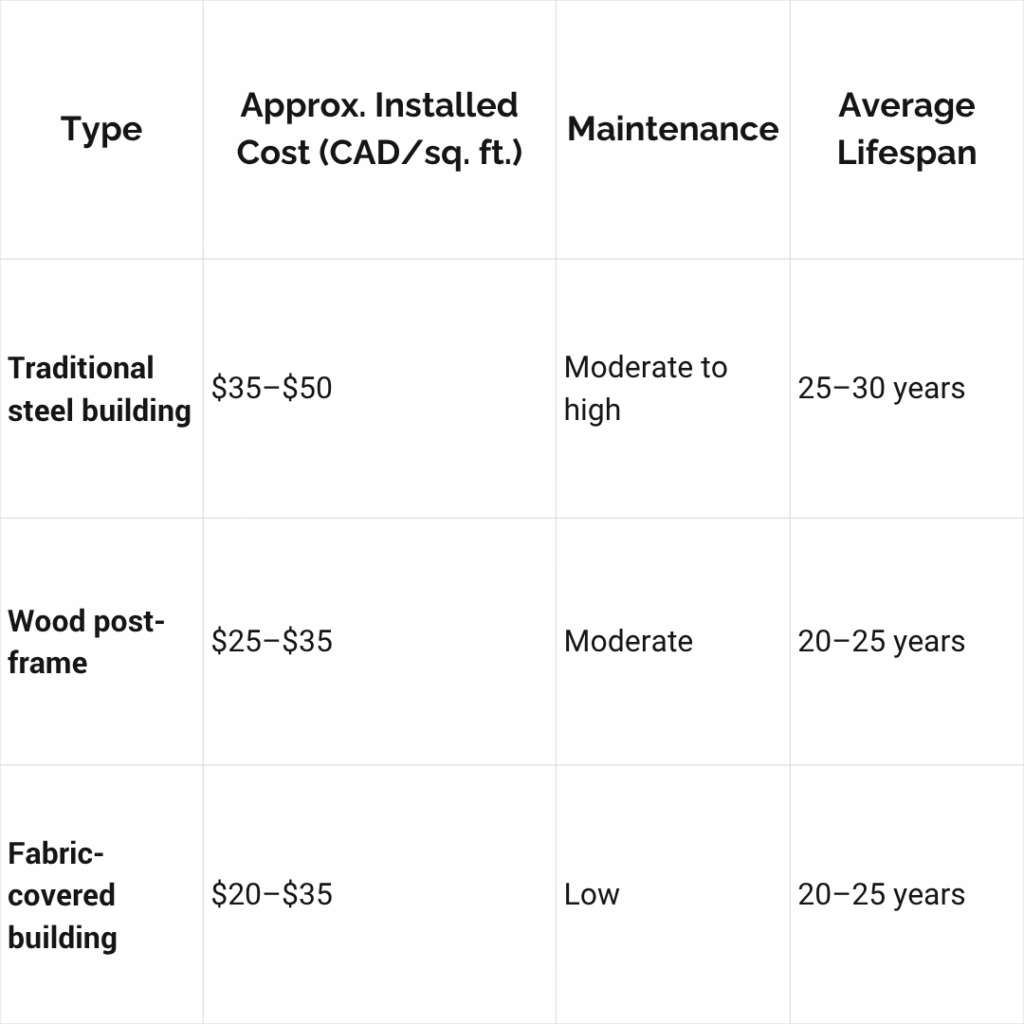

Let’s say you’re comparing a 10,000 sq. ft. storage building:

Even if the initial cost is similar on paper, your fabric building wins in the long run thanks to lower energy use, faster construction, and reduced maintenance.

That’s where the real value of fabric buildings comes in, not just what you pay, but how much value they deliver over time.

From Design to Installation: Transparency in Every Step

One thing that sets companies like SpanMaster apart is how clearly they walk you through the process. From design consultation to installation, you’ll know exactly what’s included and what’s optional.

The design-to-installation typically includes:

- Initial consultation: Define use, size, and site conditions.

- Engineering and design: Choose between arch or peak design, insulation options, and foundation type.

- Prefabrication and shipping: Everything is built in a controlled environment for precision.

- On-site installation: Crews assemble the frame and stretch the fabric cover in just days.

By the time your structure is up, you’ve already saved weeks or months compared to a traditional build, without sacrificing strength or quality. You can check out an even more detailed guide on how to install fabric buildings.

Why Switch to Fabric Building Solutions

Across Canada, businesses switch to prefabricated building solutions for one simple reason: they make financial sense.

Farmers use them for building solutions for agriculture, including hay, grain, or livestock shelters. Manufacturers and logistics companies rely on them for industrial and commercial buildings. buildings that require wide-open interiors. Municipalities love them for salt and sand storage and even emergency response shelters.

The versatility means one design can fit multiple uses, and when you consider how building solutions are the future, the decision gets even easier.

Are Fabric Buildings the Future in Canada

With rising construction costs and sustainability demands, prefabricated building solutions are the future. Modern designs now incorporate solar panels, high-efficiency insulation, and automated ventilation systems.

SpanMaster and other leading Canadian manufacturers are investing in innovation to make these structures even more energy-efficient and environmentally friendly, a big plus for businesses aiming to reduce their carbon footprint.

Final Thoughts: Cost vs. Value

Here’s the takeaway:

- Coverall building prices might vary, but the value you get from a well-designed, properly installed fabric building is unbeatable.

- You’re paying for more than a structure; you’re investing in durability, flexibility, and long-term savings.

- And when you compare the full lifecycle: design, installation, operation, and maintenance, these buildings often outperform traditional options by a mile.

So, if you’re still wondering whether a fabric building is worth the cost, the answer is yes, as long as you choose a trusted company that guides you through every phase and tailors the design to your needs.

Ready to explore your options? Learn more about arch-shaped buildings and peak-shaped buildings, or read about why prefabricated buildings save time and reduce costs. Whatever your next project looks like, a fabric building solution might just be the smartest investment you’ll make.